From concept to commercial product

Measuring mucos layers in water installations

The KWR generates knowledge about water quality. It conducts research and translates scientific knowledge into applicable practical solutions. One result of this is an instrument that can measure the formation of a slime layer (biofilm) in water pipes. The instrument has proven its practical applicability in the concept phase and is now making the step to the market. Our engineering department understands what is needed for this and has taken on the further development of this test instrument.

Chemically inert and plug-and-play: The preconditions

The CBM Continuous Biofilm monitor - as the device is called - is innovative. It can quickly detect problems such as blockages in pipes and deterioration in microbiological water quality. This improves the purification, storage and distribution of water. The intended customers for this system are water companies, which still take water samples from consumers' taps. The device to be designed had to be plug-and-play, chemically inert and samples had to be easy to collect.

That is why, when developing this product, we looked closely at:

- Applicability

- Design

- Cost of components

- Cost of assembly

- Deliverability

Our engineering department did this in continuous consultation with the scientists from KWR and Milispec (the company that markets this instrument).

The design with PVDF couplings

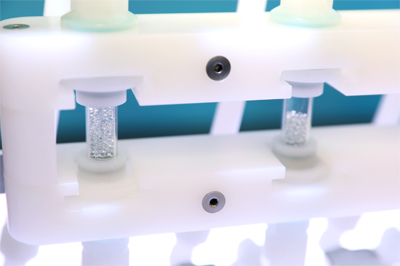

The CBM consists of glass sample ampoules with glass beads through which water flows continuously. Micro-organisms from the water adhere to the glass surface and grow, creating a layer of mucus (biofilm). The glass tubes must be easy to remove in order to be tested in the laboratory for the deposition of microorganisms (by weighing them). The precision of the measurement depends on the quality of the glass tubes, which are made by hand.

In this design we have used PTFE hose, PVDF couplings and VA flowmeters with integrated needle valve. As a system it is integrated in a compact aluminium and PVDF frame.

Our engineers designed the new instrument. The first prototypes were produced in our assembly department.

A controlled environment is needed to measure the formation of biofilm. Preferably with the possibility to measure the deposition (semi) continuously. That is why design is important. The glass tubes must be easy to change and not introduce any contamination. In addition, a smart placement of connectors makes the device easy to apply in an existing situation.

Cooperation between all parties

KWR and Milispec have already shown the prototype instrument at the Waterbeurs and Horticontact fair and there is already a lot of interest from water companies and agriculture and horticulture.

We are not scientists in the field of water quality, but we do have very good engineers who know everything about the transport and treatment of liquids. The strength of a project like this lies in the cooperation between all parties involved. Our passion for technology goes hand in hand with the innovative nature of this type of engineering project.

Teesing Systems & Engineering brochure

Teesing has its own engineering department which can develop parts and assemblies in consultation with its customers.

Read more in our Systems & Engineering brochure.

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560