Connectors for leakage testing

Special connectors clamping inside the thread / bore

Car makers all over the world have begun to master a key step in automobile manufacturing: quality control. In any industry, quality control is a process that is used to insure that a product is free from bugs, operational issues and any number of other problems. In auto manufacturing, that means cars go through rigorous testing to make sure they are well-designed, safe and comfortable.

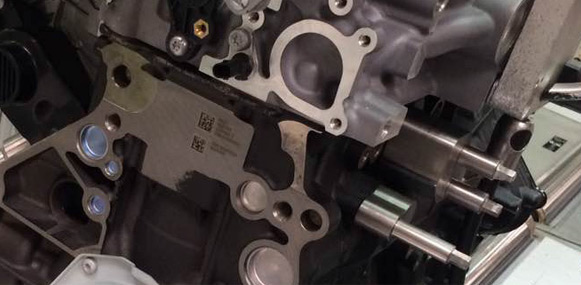

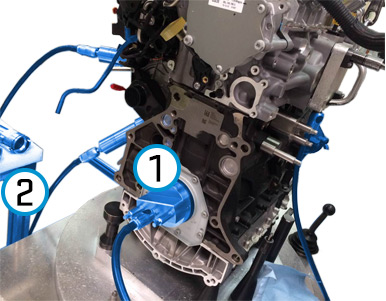

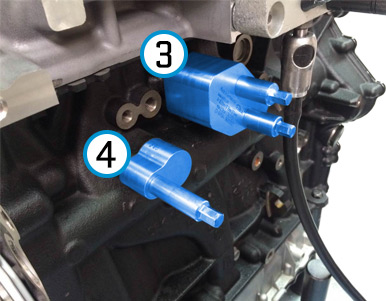

For this specific application a customer in the Dalian area used these connectors for leakage tests of car engines during their assembly. The test pressures are nearly 1 bar and the test temperature is “room temperature”. The medium is air.

Improving the assembly process

To ensure the quality of the engine and speed up the assembly process, test connectors specially made for each engine are a great tool for every modern test bench. Every engine is tested for leaks and if it fails the examination, it is rejected and will go back in the test process. This strict procedure avoids product recalls which cause considerable financial consequences in a later stage of the product lifecycle.

Shorten production time

In the past the assemblers screwed a plug in the thread connection of the engine manually for each connection to connect and disconnect the engine. With the test connectors a reliable pressure-tight connection is created in a few seconds and make the test process easy to operate. The production time goes down resulting in savings and even more importantly, fewer injuries.

For every connection a solution

The connectors are simply placed onto, over or into the inlet of the test piece. Labor-intensive screwing onto the thread connection is no longer necessary. For the people working in the factory this leads to fewer physical complaints, which are often the result of frequent repetitive operations. Complex testing devices are a thing of the past.

Teesing can not only give you technical advice about the right connector for your application but can deliver a complete testing solution including components, spare parts and other extensive servicing.

Benefits

- Pressure-tight connection in seconds

- No hand tightening needed

- Jaw locking mechanism

- High-grade materials

- Special version possible for specials needs

- Ergonomic design

- Different actuations available

- Automation possible

- Dangerous amateurish testing devices are eliminated

- Minimum wear and tear

- Easy maintenance

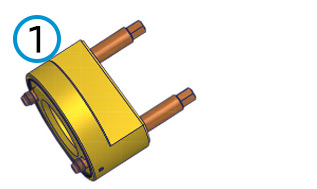

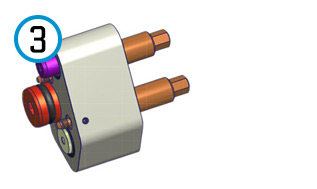

- Special unit gripping inside the bore

- Connector is fixed by screwing bolt which grips inside the internal thread

| Connection type | Diameter / Bore |

| Application | Standard Application |

| Actuation | Manual Clamping Manipulation |

| Seal material | NBR |

| Pressure | Max. 6 bar |

| Medium | Air |

| Type of clamping | Clamping inside the thread |

| Body Material | Corrosion Resistant |

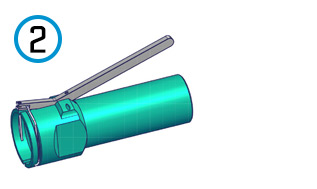

- Special unit gripping inside the bore

- Connector is fixed by screwing bolt which grips inside the internal

| Connection type | Diameter / Bore |

| Application | Standard Application |

| Actuation | Manual Clamping Manipulation |

| Seal material | NBR |

| Pressure | Max. 2,5 bar |

| Medium | Air |

| Type of clamping | Clamping inside the thread |

| Body Material | Corrosion Resistant |

| Diameter | 38,5 mm |

- Special unit gripping inside the bore

- Connector is fixed by screwing the bolt which is gripping inside the internal thread

| Connection type | Diameter / Bore |

| Application | Standard Application |

| Actuation | Manual Clamping Manipulation |

| Seal material | NBR |

| Pressure | Max. 6 bar |

| Medium | Air |

| Type of clamping | Clamping inside the thread |

| Body Material | Corrosion Resistant |

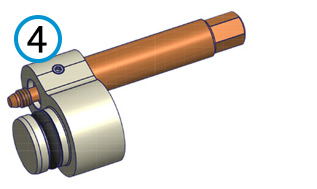

- Special unit gripping inside the bore

- Connector is fixed by screwing bolt which grips inside the internal

| Connection type | Diameter / Bore |

| Application | Standard Application |

| Actuation | Manual Clamping Manipulation |

| Seal material | NBR |

| Pressure | Max. 6 bar |

| Medium | Air |

| Type of clamping | Clamping inside the thread |

| Body Material | Corrosion Resistant |

| Diameter | 20 mm |

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560