Purifier configurator

Use your system parameters to select the right purifier.

Configure the correct purifier for your application on this page by selecting the maximum flow rate, maximum inlet pressure, inlet gas and impurities to be removed. The configuration will suggest which purifier you need, our sales team can give you more information about the life cycle, connections, specifications and applications..

Max. Flow Rate

Ingaand Gas

Impurities to be removes

Hydrogen (H2)

Water (H2O)

Carbon Monoxide (CO)

Carbon Dioxide (CO2)

Nitrogen (N2)

Nitrogen dioxide (NOx)

Amines

THC

NMHC

PURIFIER SUGGESTION

This is only a suggestion, if in doubt please contact our sales team.

+31 70 413 07 50

Point of use purifiers

The point of use purifiers are designed for (ultra) high purity applications that require impurity levels in process gases to be 100ppt (parts per trillion) or less.

Specifications

Material: SS316L

Max. operating temperature: 400°C

Max. operating pressure: 17.24 bar (vessels) 10.24 bar (in-line and panel purifiers)

Max. flow rate: 4.5 to 300 SLPM for 0,1µm filtration. 1.5 to 100 SLPM for 0,003µm

Nominal flow rate: 0,3 to 20 slpm (depending on vessel size)

Filtration: 0,1 µm standard, optional 0,003µm

Outlet purity: <100ppt

Pressure drop: <2 psid

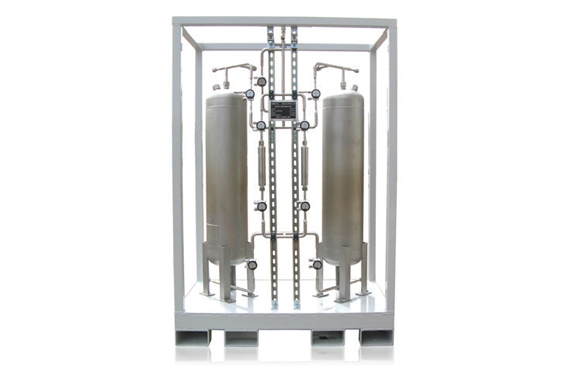

Micro bulk purifiers

The micro bulk purifiers offer moderate flow rates, serving high purity and permanently installed gas delivery systems.

Specifications

Material: SS316L with powder coated steel unclosure

Max. operating temperature: 400°C

Max. operating pressure: 17.24 bar vessels

Max. flow rate: 100 to 1500 SLPM for 0,1µm filtration. 60 to 1000 SLPM for 0,003µm

Nominal flow rate: 7 to 225 slpm (depending on vessel size)

Filtration: 0,1 µm standard, optional 0,003µm

Outlet purity: <100ppt

Pressure drop: <2 ATM

Any Questions?

More information about our products, services or looking for a custom solution?

Please contact our Sales Engineers.

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560