Reliable sustainable energy, 24/7 availability

Jos Wolbrink - Procurement

"Our sustainable energy systems have to be robust and 100% reliable; Teesing's products contribute to this."

GeoComfort’s strength lies in the development, building and installation of heat pump systems for the non-residential building sector. In their doublet system they make use of a heat and cold source, which is alternately used in summer and winter to store cold or hot media in the ground. The GeoDoublet consists of one or more source pairs, site piping and a prefab frame that supports various types of equipment, including a heat exchanger, reverser, control unit with a metering unit, assembled and cabled into a so-called GD-SKID. The doublet system is supplied as an energy storage system and has a capacity in the 20 to 250 m3/h range.

The GeoDoublet is constructed using high-quality components such as the Melotte underwater pump and injection valve, a Tranter exchanger and Serto 316Ti stainless steel components, making it suitable for fresh as well as salt water.

Enjoyment of energy savings without worries

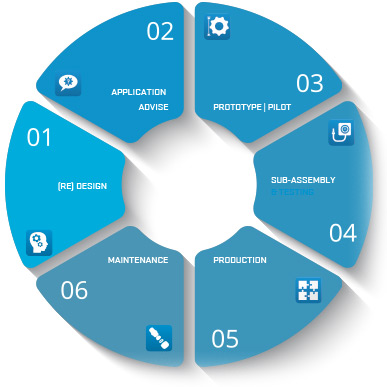

The sustainable energy system has to pay for itself by providing a high level of comfort, but especially maximum energy savings. After commissioning the system, it is therefore important to monitor it critically and where necessary optimally adjust it to the user’s needs. As a partner that contributes to the development of solutions, this is exactly where Teesing can add value during the design process. Our customers go through different product life cycle stages. We understand very well that the majority of them continues to invest in the development of new products to ensure that their business continues to grow.

During development we contribute solutions in our area of competence: the provision of a comprehensive package of products and services relating to the transport of gases and liquids from source to process. In this respect we support our customers during different phases, such as concept development, research, development, testing, production, installation, maintenance and, if necessary, redesign in order to remain competitive in their area of expertise.

We support our customers during different phases.

Sustainable production, installation and maintenance of subsystems

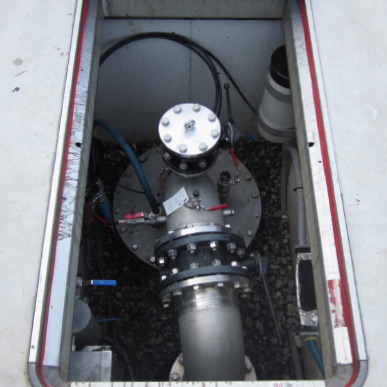

It is important for the groundwater to remain under pressure and a pilot cabinet is used for this purpose. This cabinet is mounted in the well above the source and could end up under water. The possibility of a leak must be nil and due to the limited space everything inside the cabinet is built small. The assembly of essential connections in smaller spaces brings complications and risks with it, which is why GeoComfort has opted for the reliable Serto system. To prevent problems during the operating phase, the clamping ring and the tubing are pre-assembled. The assembly/disassembly of traditional couplings takes a great deal of time and energy in comparison with Serto’s radial system.

Benefits of the proposed system

- 40% time savings in production and maintenance, resulting in a reduction of the overall operating costs.

- Reliable leakage proof connection with ‘larger’ diameter dimensions.

- Pre-assembly with SertoTool, SertoMatic or manual pre-assembly with the Serto accessory tool make a plug & play installation possible.

- This is a flexible modular system, which makes it easy to adapt existing systems.

Connections from the pilot cabinet to the external system

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560