Development of hydrogen fuel cell

New liquid cooling system saves 20% of the energy

In bioreactor systems, optimal mass transfer of gases like O2 (oxygen) or CO2 (carbon dioxide) is difficult to accomplish. Oxygen, in particular, is poorly soluble in water, and even less so in cell culture and fermentation broths. Oxygen transfer is aided by agitation to mix nutrients and to keep the cell culture or fermentation homogeneous. There are limits to agitation speed due to high power consumption as well as damage to organisms resulting from excessive tip speed.

Agitation alone does not provide adequate mass transfer. Using a porous metal sparger greatly increases mass transfer rates in this equipment. The introduction of gases into stirred or unstirred reactor vessels via millions of tiny bubbles increases the gas-to-liquid contact areas allowing for optimal mass transfer rates. In-tank applications, with sparging elements located inside the tank, can be batch or continuous flow, with or without agitation.

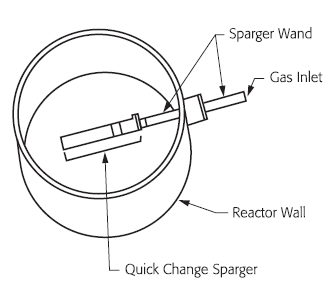

With the Quick Change Sparger system (see Figure 1), the porous metal element can be removed and replaced after each use. This eliminates the need to re-weld the tip or clean the entire assembly.

Porous metal applications in the biotechnology and pharmaceutical industries include:

Bioreactor/fermentor process gas spargers

Steam filters

Steam spargers

Gas-line filters

No need to reweld the sparger tips

After each batch, a new tip can be installed on the end of the assembly and is ready for steam-in-place operation. Or the sparger tip can be cleaned out-of-place using a number of methods, including ultrasound or a detergent and water flush.

Either way, the Quick Change Sparger can help make sparger change out simple and easy. Changing to new clean sparger tips after each batch is an excellent method of maintaining GMP process validation methods.

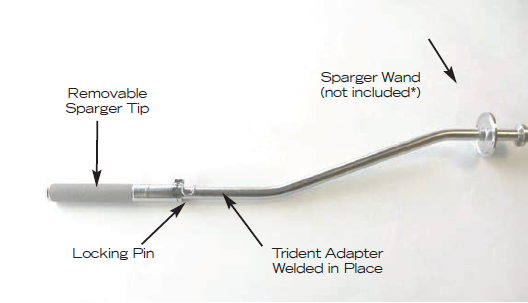

Teesing does not supply the Sparger Wand as this is readily available equipment which can be modified with the Trident adapter to accept the removable porous metal sparger tips.

✔ TIP: Download the sparger design guide & part selection.

Download now!Problems incurring while injecting oxygen or carbon dioxide into liquids

High energy costs and low performance?

Spargers need decreased agitation while achieving higher O2 or CO2 absorption.

Save welding time

With the Quick Change Sparger system the porous metal element can be removed and assembled more quickly.

High gas usage?

Spargers provide smaller bubble size for higher surface contact ratio, reducing the total volume of gas used

Internal designers unfamiliar with proper sizing and design?

Our team of engineering and application experts are available to assist in sizing or overall design.

Typical sparging applications

Bioreactor mixing

O2 and CO2 injection for mixing liquids in a reactor or fermentor.

Water waste treatment

Adding O2 and O3 to purify and supply oxygen to municipal water supplies.

Fermentation

Oxygen or air sparging to enhance cell growth in fermentation reactions.

Biofuel production

Sparging to promote effective yeast propagation in the fermentors.

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560