High purity filtering in ALD and CVD processes

Tests with 4 precursors validate 1,5 nm porous metal fiber filters

As the semiconductor industry moves to the sub-10 nm line nodes (such as 7nm, 5nm and smaller), nano-sized particles, once considered nuisance particles will be classified as killer defect particles. Particularly in ALD and CVD processes, the need to drive for new ultra-high purity gas filtration technology has become critical. On this scale filtration capabilities should be verified. We would like to share some specific information with you on the various semiconductor manufacturing environments in which these MOTT filters have proven themselves, resulting in less errors and less downtime.

High purity filtering of organometallic precursors

Mott High Purity Filters provide 9-log filtration of particles down to 1,5 nm resulting in particle-free gas. These filters are application specific designed for filtration in advanced deposition (ALD, CVD) processes. MOTT’s FLP model is specifically well suited for filtration of low vapor pressure gases, generated in a direct liquid injection system, where the process utilizes a vaporization chamber. They are ideally suited for handling vapor phase low pressure dopants or organometallic precursor vapors such as TEMAZ, TEOS, TiCl4, TDMAT, TEPO, TEB, POCl, Z4MS, Ztomcats, Trans-LC and TMB.

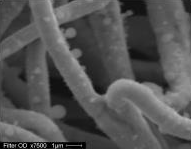

Upstream side of FLP filter

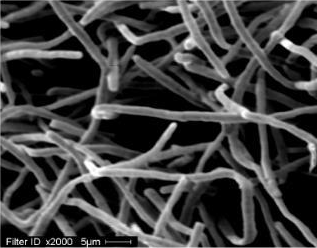

Downstream side of FLP filter

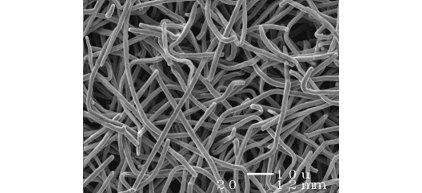

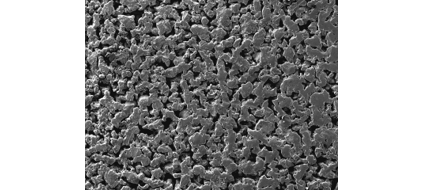

Photo: Porous metal fiber filter

Intermolecular forces do the trick

The 1,5nm filter capability is reached using their unique metal fiber filter technique. A general misconception in gas filtration is that only larger particles are captured via sieving, while smaller ones pass through the filter. A metal fiber filter uses the depth of the filter to capture even the smallest particle sizes. This process depends on particle adhesion based on intermolecular attractive forces due to Van der Waal’s force and electrostatic force.

Metal fiber filter characteristics

The metal fibre technique combines the best advantages of sintered metal filters and Teflon filters:

- 1.5 nm particle retention

- Low pressure drop

- Low density with more open structure with hydrophobic properties

- Low differential pressure variability from part to part allows for tight system control

- High temperature capable: 450°C

- High differential pressure 500 psid

More information?

More information about our products or looking for a custom solution?

Please contact our Sales Engineers.

NL: +31 70 413 07 00

CN: +86-(0)10-60576210

USA: +(1) 973 383 0691

TW: +886-(0)3-5600560

Already know who you're dealing with? Contact your salesperson directly:

Look up salesperson

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560